Compression Splice for ACSS and ACSS/TW Conductors

Installation

Instructions

Mark the conductor a distance of ½ the length of the aluminum sleeve Prior to making connection, the outer strands of the conductor should be cleaned with a wire brush or abrasive cloth

Remark each conductor half the length of the aluminum sleeve, if the mark was removed during wire brushing prior to any strand cutting, tape the end of each conductor to help maintain the round contour

Slide the aluminum sleeve over one conductor until sufficient working length protrudes from end

Cut back aluminum strands of both conductors ½ the length of the steel sleeve plus 1 ½ inch (38 1 mm) Do not nick the steel strands File any burrs, if present

Use of a cable trimming tool is recommended

Insert ends of steel core into steel sleeve making sure the ends butt solidly against center stop

Using the proper SH die set, compress steel sleeve full length making initial compression over center of sleeve

Overlap each successive compression by at least ¼ inch (6.4 mm) Complete die closure is required on all compressions

Slide the aluminum sleeve over the installed steel sleeve, centering between the two marks that were made in Step 3

Inject AFCHT filler compound into filler hole until compound emerges from both ends of aluminum sleeve

Using the proper AH die set, make the initial compression at the “start” mark on one side of center

The second compression should be made at the other “start” mark on opposite side of center Continue making compressions to the end, overlapping each by at least ¼ inch (6 4 mm)

Complete die closure is required for each compression Note: A light oil coating on the die grooves and aluminum sleeve is recommended

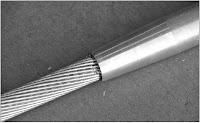

Compressed portion of splice sleeve should have a smooth uniform appearance if die flash is present, remove with a file or emery cloth Remove any excess filler compound which may have been forced out the ends of the splice